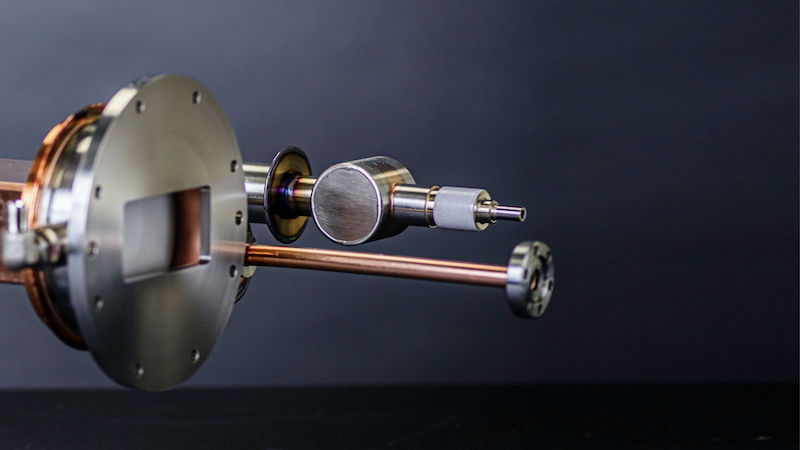

Our commitment to innovative product development has led to a new look at an old design. As mentioned last time, one of the technologies that have been submitted as a SBIR grant proposal is a new 8-liter ion pump design. As promised, let’s discuss a few of the proposed innovations in this entry.

The current ionization pumps that are commercially available suffer from loss of vacuum due to corrosion, cannot withstand bake-out temperatures greater than 450 C and use less than ideal metal-ceramic braze joint designs that result in tensile stresses that have also led to vacuum loss. These pumps were also not designed to be in operation for hundreds of thousands of hours that several applications require.

Altair Technologies will design and develop an ionization pump that solves these problems by using commercially available corrosion-resistant materials, braze alloys with working temperatures well above 450 C and braze-joint designs that dramatically limit stresses due to materials with different thermal expansion rates. These pump assemblies will not only last in excess of 15 years but will eliminate costly failures that could exceed $250K per occurrence for some large high power klystron systems such as those at the SLAC National Accelerator Laboratory. Altair will also design for cost on the new product to make sure the solution will be affordable.

So….how will we do this;

Proper failure analysis to identify the root cause of each type of failure and solving all known corrosive problems with commercially available materials will be the keystone of the design. Once we have a successful design, Altair will confirm success by performing accelerated environmental testing of the new pump design and alongside a commercially available ion pump.

A known area of failure is the various braze joints in the assembled device. With Altair’s extensive experience in brazing techniques and design, we plan to study braze joint failures via a finite element analysis of the existing industry-standard design. Once these failures are understood, Altair will draw on its proven designs known to reduce tensile stress and implement them in the design. This is a common Altair practice and we excel in it.

The 8-liter pump is a staple in the high vacuum community and with the increased demand for longer-lived vacuum systems, a “better” pump is needed. Altair is ready to answer that need.