Brazing Services

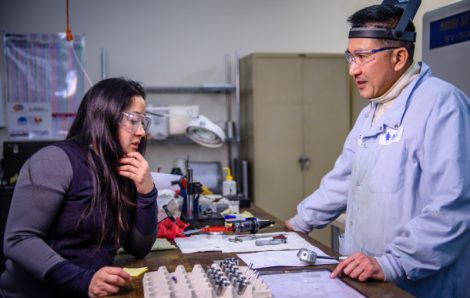

We are a brazing company and global leader in the field of advanced material joining technologies for high vacuum applications. Our brazing services leverage precision vacuum and furnace brazing technologies to provide our customers cost savings, batch processing and the highest quality in the industry.

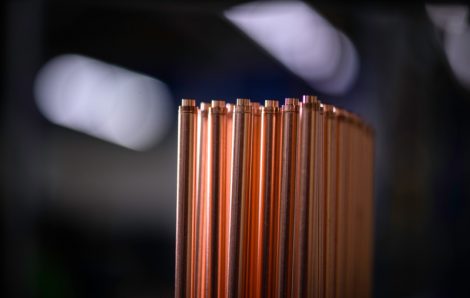

We braze and clean fire virtually all low vapor pressure metals and ceramics such as OHFC Copper 101,Stainless Steel (SST), Kovar, Monel, Tungsten, Cupro-Nickel, Titanium, Aluminum, Alumina, Silicon Carbide and many more.

Our furnace brazing services or vacuum brazing services are available via consignment or turnkey production services. We encourage the turnkey route because it lowers overall risk for you. Consignment is a good fit when customers are experts in braze-joint design and can provide high-quality pre-machined material for processing. If desired, we can also provide NADCAP certified heat treating, stress-relieving, tempering and secondary finishing operations via our in-house CNC machining department upon request.

Brazing Services

We are a brazing company and global leader in the field of advanced material joining technologies for high vacuum applications. Our services leverage precision vacuum and furnace brazing technologies to provide our customers cost savings, batch processing and the highest quality in the industry.

We braze and clean fire virtually all low vapor pressure metals and ceramics such as OHFC Copper 101,Stainless Steel (SST), Kovar, Monel, Tungsten, Cupro-Nickel, Titanium, Aluminum, Alumina, Silicon Carbide and many more.

Our furnace brazing services or vacuum brazing services are available via consignment or turnkey production solutions. We encourage the turnkey route because it lowers overall risk for you. Consignment is a good fit when customers are experts in braze-joint design and can provide high-quality pre-machined material for processing. If desired, we can also provide NACAP certified heat treating, stress-relieving, tempering and secondary finishing operations via our in-house CNC machining department upon request.

14

Brazing Furnaces

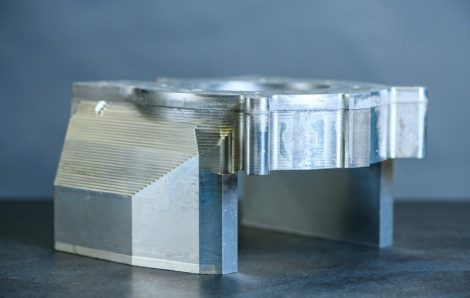

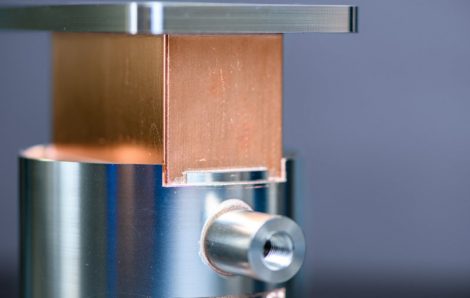

Furnace technology provides the highest quality joints and is the only technique well adapted for complex geometries, ceramic-to-metal bonding, large/massive parts, or highly reactive materials because assemblies are heated uniformly and multiple joints are processed simultaneously. We primarily supply services and products into high-vacuum, Ultra-High Vacuum (UHV), or “clean” applications and DO NOT use any flux in our advanced material joining processes. Our services include atmosphere brazing, hydrogen brazing, vacuum furnace brazing services, diffusion bonding, bakeout for high vacuum applications and heat treating.

Furnace Brazing Capabilities

• 10” to 48” Diameter

• Hydrogen Wet or Dry

• High Vacuum 10-5 & 10-6

• Inert Gas, Blends, Cascade Controllers

Vacuum Furnace Specifications

• 2 PVT Vacuum Furnaces

• 28” x 28” x 28” Hot Zone

• 48” x 28” x 28” Hot Zone

• Temperature Profile Recording

Benefits of Brazing

A new world of design possibilities opens up with today's Vacuum & Furnace Technologies

Work with us to engineer complex designs never before thought possible; every day we help our customers understand joint design and how to engineer parts for our vacuum and furnace brazing services. We are open and collaborative to discuss your requirements, provide DFM (Design for Manufacturability) guidance and help you actualize a low-cost solution with high yield.

Brazing Applications

Products Use Cases

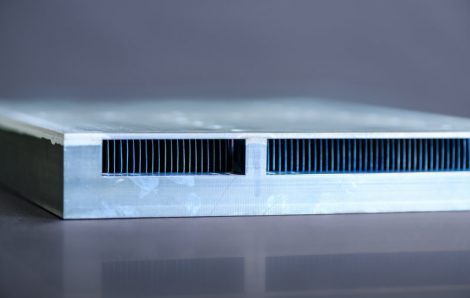

Heat sink and Electronics Cooling

Liquid Cold or Cooling Plates

Flat Tube Heat Exchangers

Heat Pipes & Heater Tables

Vacuum Chambers (Semiconductor)

Electro-Static Chucks

Electric Vehicle (EV) Components

Micro-Channel Heat Exchangers

EV Battery Cooling/Heating

UHV Heater Modules

Pressure Vessels of All Sizes

Subassembly Packaging of Sensors

Hydraulic flow boxes

Thermodynamic Engines

Deposition Chambers & Stages

Plate Heat Exchangers

Solar Panels & Energy Equipment

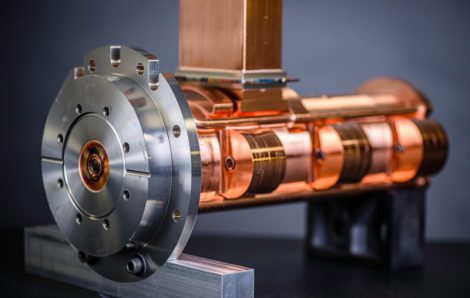

RF Power & Linear Accelerators

Dual Bell Sauder Bakeout Station

A processing step for UHV (ultra-high vacuum) applications. We continue to add core and complementary capabilities like bakeout and have always been leaders and innovators in this regard.

• 6 Independent Cryogenic Ports

• Two Independent Bells

• x10-9 scale vacuum pressure

• Temp. > 600°C and > 1000°C

• Automated Controls

• Ultra-High Vacuum (UHV)

• Efficient Device Conditioning

• Flexible Configuration

• RGA Measurements

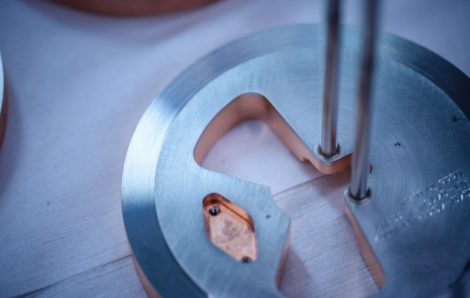

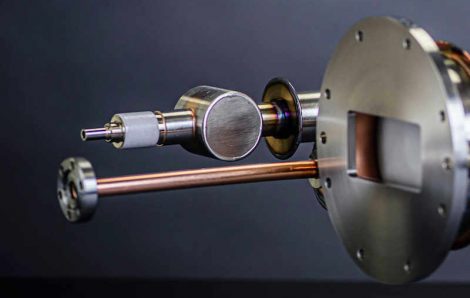

Material Joining without the use of filler

High compression and temperatures cause atoms to diffuse into the adjacent material for metal, copper, and titanium. This particular bonding process is commonly used on linear accelerators and mini-coolers, where braze joints and braze fillets can shift the resonant frequency of a cavity or add a very thin thermal shunt layer which is avoided in diffusion bonding.

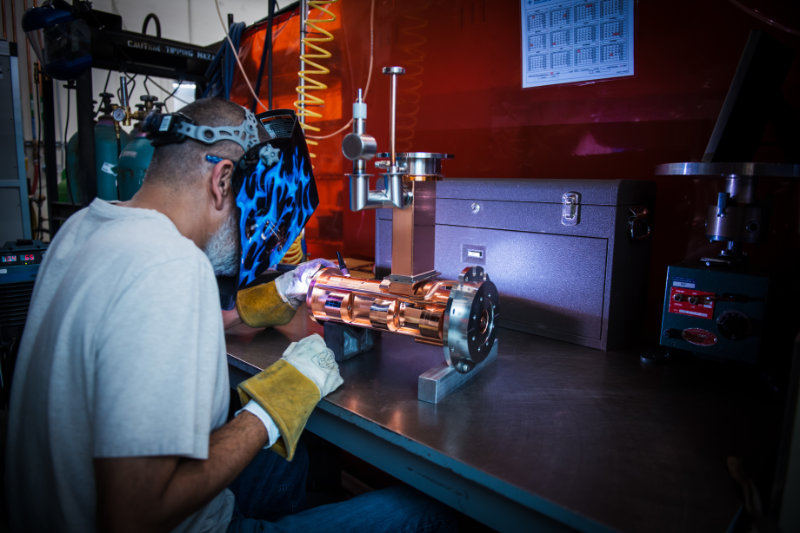

Precision Welding

Includes Tig and Spot Welding

Precision welding rounds out our full spectrum of material joining capabilities to support our contract manufacturing and turnkey services. Welding is both an art and a science. We take pride in our beautiful and full penetration welds because they are a prime example of our commitment to quality and the highest standards of fabrication.

We weld Titanium, Nickel, Stainless Steel, Platinum, Kovar, and Moly for spot, stitch and continuous hermetic (vacuum-tight) welds.

Looking to get it right the first time?

Brazing Aluminum

The best way to braze aluminum assemblies is in high vacuum furnaces that are specifically designed with the multi-zone …

Brazing Stainless Steel

Stainless is a low vapor pressure material best suited for wet or dry hydrogen brazing, depending on removal of oxides …

Brazing Ceramics

We routinely braze ceramics, particularly Alumina, but can also braze Zirconia, Quartz, Fused Silica, BeO, AlN, Si, SiC …

Brazing Metal – A Comprehensive Overview

We braze low vapor pressure metals like Copper, Stainless Steel, Kovar, Moly, Iron, Monel, Cupronickel, Nickel, …

Furnace Brazing Copper in Hydrogen Gas

Furnace brazing copper in hydrogen gas is the best method to braze copper for accuracy, joint-strength and high-vacuum …