Role of the Linear Accelerator (LINAC) in Security and Cargo Inspection –Part II

By: Samy Hanna, PhD, PE. – Consultant

In my previous post on X-Ray Cargo Inspection, I described some of the Linear Accelerator (LINAC)–based high energy X-rays cargo scanners. In this post, I discuss some of the more recent advances in cargo inspection techniques used in the Security Industry.

Recent cargo inspection techniques have benefited from the advancement in imaging and pattern recognition techniques that have been developed in the last three decades. Most of these advanced techniques were originally developed for improved medical diagnostics and enhanced images for non-destructive testing (NDT). Examples of these techniques are the X-ray computed tomography (CT), the use of dual-energy X-ray systems, and combining these two techniques into the dual-energy CT imaging technique. Additionally, recent advancements in X-ray detectors have resulted in more sensitive, lower cost, and higher-resolution imaging systems.

X-Ray Computed Tomography

X-ray computed tomography (CT) is widely used for medical diagnostic, NDT, and, more recently, for security purposes like baggage inspection. In this technique, cross-sectional images “slices” of an object are numerically reconstructed from X-Ray projections at various angles around the object. Using specialized computer programs, these cross-sectional images are combined to produce a two or three-dimensional image (as in medical CAT scans). CT scanners measure the attenuation coefficient of the scanned object. The attenuation coefficient depends on the material being scanned and is also a function of the energy of the incident X-ray photons. In most current cargo inspection CT systems, the scan is performed with an X-ray source of a specific energy spectrum and it is not possible to determine the chemical composition of the scanned materials. Fortunately, some cargo inspection systems started recently to use dual-energy X-ray systems. These systems yield material discrimination through the comparison of the attenuation of X-ray beams having two different energy spectra.

Dual Energy X-Ray Systems

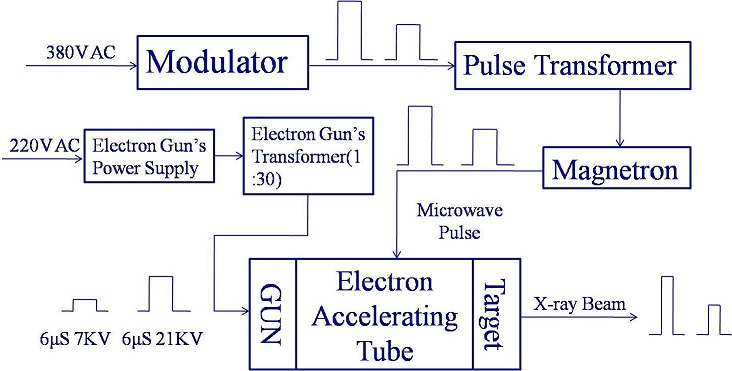

Recently, dual high-energy X-ray systems have been proposed for the detection of special nuclear material in cargo containers. They use a Linear Accelerator that can be switched between two modes of operation to produce two different energies. In one mode of operation, 6 MeV electrons are generated producing (through the bremsstrahlung effect) X-rays with energies from 0 to 6 MV. In the other energy mode, the Linear Accelerator generates 9 MeV electrons producing X-rays with energy spectrum from 0 to 9 MV. Photons of two different energy levels interact with matter differently. The high atomic number (Z) materials are much more opaque to 9 MV photons than to 6 MV photons, so high Z materials such as uranium and plutonium can be recognized. Then, a special computer algorithm estimates the size and atomic numbers of individual objects and, based on that data, determines the level of concern and the possibility of the inclusion of such dangerous materials. We can get higher electron energy with higher RF power and lower electron current, and vice versa. Thus, we can achieve the interlacing dual-energy X-ray delivery by controlling and changing two variables in the Linear Accelerator, the injected beam current and the RF source’s (Magnetron or Klystron) power from pulse to pulse. Fig. 1 shows an RF scheme as an example for varying the electron beam energies pulse-to-pulse, [1, 2]. However, an important requirement to achieve material identification is to have a very stable dose rate x-ray pulses for both energies.

Dual-Energy CT Imaging

For X-Ray Cargo Inspection, Dual-energy CT combines the above two advanced approaches into one technology where the object is scanned with two different X-ray energy spectra. It allows not only the reconstruction of 2D images of the objects in a cargo container, but can also be used to estimate the density and the effective atomic number of different objects. In the security domain, these numbers can play an important role in the detection of explosives and dangerous materials such as uranium and plutonium.

Advancement In The X-Ray Detector

The X-ray detector is where the photons, transmitted through the cargo, are converted into visible light (scintillation) and measured by sensitive photo-detector elements. The field of X-ray detectors for cargo scanning has benefited significantly from advancements achieved by design and manufacturing engineers building detectors for medical diagnostics. Some of the improvements for cargo detectors are the improvements in sensitivity and larger dynamic range.

[1] S. Hanna. “RF Linear Accelerators for Medical and Industrial Applications”, Artech House Publishing, 2012.

[2] C. Tang, et al., “Electron Linear Accelerators for Cargo Inspection and Other Industrial Applications”, Proceedings of International Topical Meeting on Nuclear Research Applications and Utilization of Accelerators, Vienna., Austria, May 2009.