Security and Cargo Inspection use High-Energy X-ray Linear Accelerators (LINACs)

By: Samy Hanna, PhD, PE. – Consultant

Many ports around the world rely on X-ray scanners to inspect cargo for nuclear materials or weapons and prevent contraband from entering their countries. Conventionally, these have been gamma-ray scanners based on radioactive isotopes such as cobalt-60 or the common DC X-ray tubes. In spite of the recent advancement in X-ray tube technology, they are still limited in energy output to about 450 KeV. This energy level limits the penetration power to less than 10 cm of steel. For this reason, an increasing number of ports are nowadays turning to Linear Accelerator (LINAC)–based high energy X-rays cargo scanners.

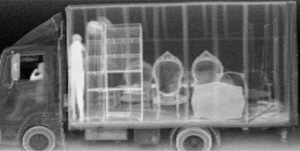

In the security and cargo inspection applications, LINACs are used to accelerate electrons to energies of 3-9 MeV capable of producing high-energy X-rays that penetrate deep and give the port inspectors information about the nature of the cargo. The denser the object, the more the attenuation of the projected X-ray is and the darker the image produced for such an object, thus allowing the X-ray scanner to reveal the basic shapes of objects and differentiate between different objects inside a cargo container. The optimal energy needed depends on the X-ray detector used, the size of the cargo container to be inspected, and the overall scanning system design. However, many cargo screening system manufacturers have found that 3 MeV to 6 MeV LINACs produce the best tradeoff for overall performance and cost. If the energy of the LINAC is below 2 MeV, the X-ray penetration is low for densely loaded containers. On the other hand, LINACs accelerating electrons to energies significantly above 9 MeV would require extensive shielding and can produce neutrons, an undesired byproduct.

Another consideration in designing and manufacturing LINACs that are used in security and cargo inspection scanners is the choice of the rate at which the X-rays are emitted, given that the objects being inspected are moving with respect to the LINAC-based X-ray source. Because of power considerations, LINACs used in this application are pulsed LINACs and not continuous-wave (CW) LINACs. The pulses are about 4 microseconds long and have adjustable pulse repetition frequency (PRF) between 50 to 500 pulses per second. Such relatively high PRF allows for reasonable speed of scanning and hence acceptable flow of cargo, while not compromising the quality of the images.

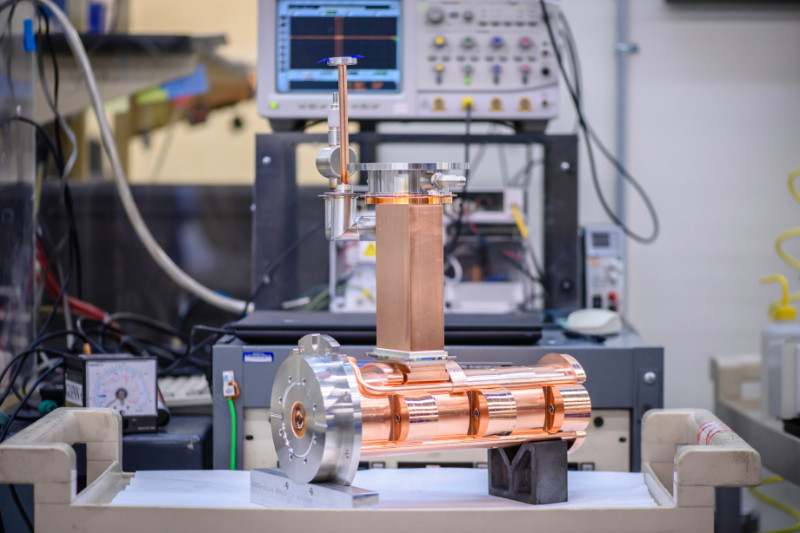

There are two approaches for inspecting railcars and cargo containers in high-volume operations using the scanning unit based on LINACs, [1]. In the first approach, the truck that is carrying the cargo container pulls up to a scanning station (which looks like a car wash construction) that has a LINAC and the target producing the X-ray on one side and a detector on the other side, Fig. 1. While the truck is moved slowly through the unit, the fan of X-rays that has passed through the truck and its cargo is detected by a linear array of scintillation detectors. A transmission image is built up in real-time revealing what is inside the container. In the second approach, a mobile scanning system is mounted on a special vehicle, Fig.2. During operation, the mobile scanning system pulls right up to the truck that is carrying the cargo container being inspected. The mobile scanner unit moves up and down parallel to the container. The mobile scanner has the LINAC and its X-ray target on one side and a detector on the other side of the truck. An image is collected based on the X-rays that have passed through the truck and its cargo.

In part-II of this post, I will discuss some of the recent advances in cargo inspection techniques. Talk to you in my next Linear Accelerator Post.

[1] S. Hanna. “RF Linear Accelerators for Medical and Industrial Applications”, Artech House Publishing, 2012.